Injection Moulding

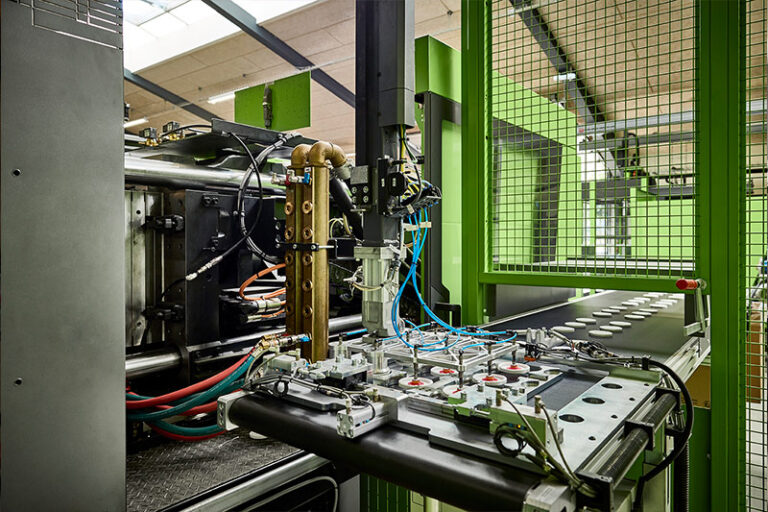

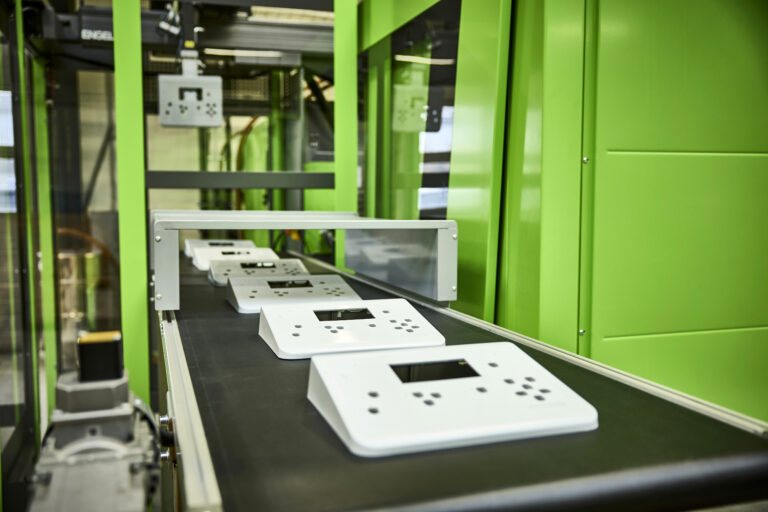

Our new fully electric and hybrid injection moulding machines operate with high speed and precision.

We are proud that A.K. Iversen is powered exclusively by wind energy, resulting in a very low CO₂ footprint.

All machines are equipped with robotic solutions that can be easily adapted to meet specific customer requirements.

We handle a wide range of plastic materials — from types that can replace rubber to glass-fiber reinforced types used in constructions where they can replace steel or aluminum.

Plastic is an almost limitless material, and is infinitely recyclable.

Post-Processing

Post-processing plays a crucial role in our production process, ensuring that the final product meets our customers’ exact specifications.

We offer a wide variety of post-processing options for plastic components, including surface treatments such as painting and chrome plating, as well as various types of printing.

We also provide assembly services and post-processing of moulded parts in our 5-axis machining center.

Ultimately, we are proud to deliver a complete product tailored to the customer’s specifications.

Custom Solutions

We understand that not all projects can be solved with standard methods.

That’s why we offer tailored custom solutions to meet unique requirements.

Our extensive experience and flexibility enable us to tackle even the most complex tasks, and pioneer innovative solutions.

If your project requires special materials, advanced technologies, or customized processes, our team is ready to develop and implement the most effective strategy.

Our Machinery

Our state-of-the-art machinery consists exclusively of fully electric and hybrid injection moulding machines, ensuring optimal energy reduction and significant CO₂ savings. All machines are equipped with various robotic solutions to handle both large and small production series with high efficiency and precision. With deliberate overcapacity in our machine park, we can accommodate urgent orders and offer fast lead times, making us highly flexible in meeting our customers’ changing needs.